Product Description

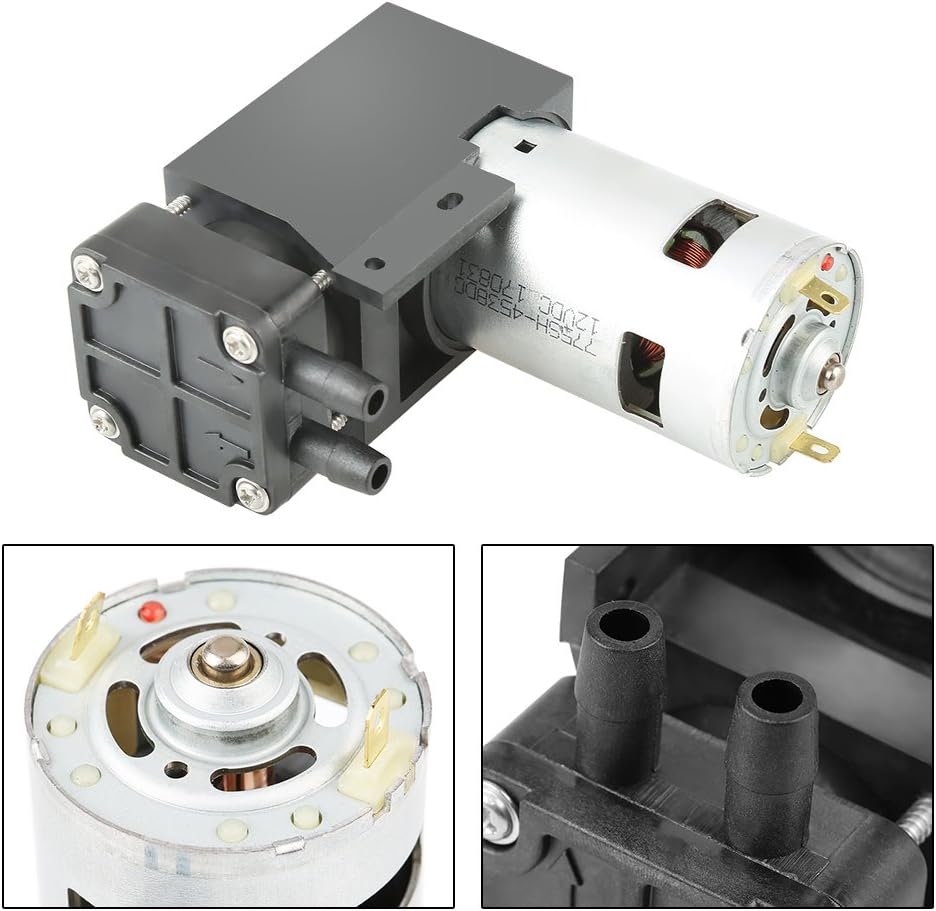

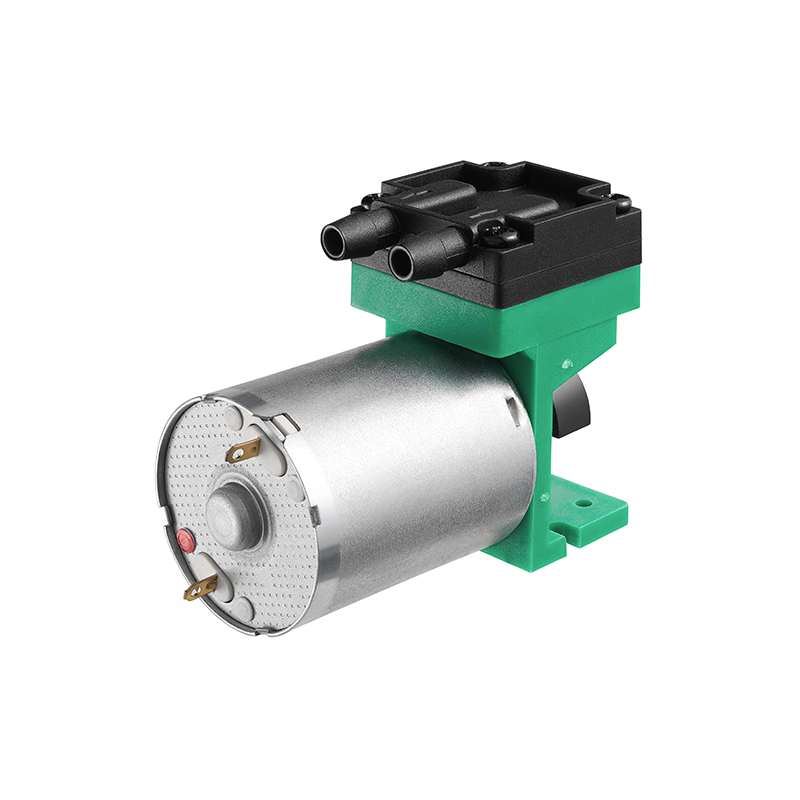

High-Performance China Micro Vacuum Pump

Micro Air Pump/Brush DC Diaphragm Pressure Vacuum Pump/Mini Compressor Air Pump

Manufacturing Factory

Product Description

To get more Technical data, Please Send a message!

|

pump (1.5V~29V) |

Miniature pump/Air pump/Vacuum pump/Water Pump/Atomization Pump/Foam pump/Nasal aspirator pump/Check valve Pump/Piston pump/Gear pump/Water Vapor pump/purpose air pump/Extraction pump/Dual pump/Vacuum air pump/Peristaltic pump/Miniature air pump |

|||

|

valve (3V~12V) |

Air Valve/Normal shutdown/Solenoid valve/Normal shutdown/Two-way valve/Water valve/Three-way valve |

|||

|

motor (3V~24V) |

Speed ratio DC brushless planetary motor/DC brushless motor of vacuum cleaner/DC brushless motor/Brushless DC motor for UAV |

|||

|

Feel free to send us your parameter and we will quote you for free! |

||||

|

We give you professional product solutions based on the product information you provide, including customization. |

||||

|

No big quantity is needed for your order. Small orders are welcomed. |

||||

|

We can also add your logo or design to your product with a laser marking machine. |

||||

|

Customized series |

||||

|

Tell us the product you want, we will provide you with professional customization of the product. |

||||

|

Support oem/odm, support proofing, support packaging, support voltage, support size, support design, etc. |

||||

|

Product Usage |

||||

|

Pump: electronic sphygmomanometer, household appliances, Sprayers, coffee machines, soap dispensers, beauty and medical products, Floor Scrubbers, nebulizer, Breast pump, oral irrigator, massage, eye massage apparatus, vacuum fresh container, electric aircraft cup, DC oxygen pump, Airwave physiotherapy machine, aroma diffuser, Beer brewing machine, Scrapping instrument, nasal aspirator, Intelligent wall breaker, drinking fountain, Car massage seat, Foot Massager and DC atomizing pump ect. |

||||

|

Solenoid valve: Smart fresh Fruit cup, Red wine preservation device, electronic sphygmomanometer, massage, household appliances, Sprayers, coffee machines, soap dispensers beauty and medical products etc. |

||||

|

DC brushless motor: massage, household massage gun, household appliances, electrical tools, water pump etc. |

Company Profile

HangZhou CHINAMFG Motor Co., Ltd., founded in 2pcs, number of employees 600+, we have patent certificates for various products in addition to CE certificates, we provide product parameter customization

Our main products include micro air pumps, water pumps, air valves, electromagnets, micro DC motors, and other micro motors.

Our products are widely applied in medical devices, electronic sphygmomanometers, massage armchairs, smart instruments, automation devices, coffee machines, smart cleaners, breast pumps, and blood monitors. etc

We have a group of highly experienced engineers who specialized in the development of micro air pumps, micro air valves, and micro motors for over 21 years.

FAQ

1. What can you buy from us?

Air Pump / Solenoid Pump / Water Pump, Solenoid Valve / Water Valve, Valves, Micro DC Motors / other micromotors

2. What can we do for you?

We can develop new products for you or modify parameters such as flow, current, and pressure on existing products. We can OEM, and ODM.

Batch orders will be shipped in 30 working daysSample order will be shipped within 3 working days.

3.How long is the deliver[Producing] and shipping ?

Always a pre-production sample before mass production;Always final Inspection before shipment.

4. How can we guarantee quality?

The warranty is 3 year. We deliver new and faultless products. Also, we are responsible for repairing and replacing the defective ones in the warranty period meanwhile we provide life-long free technical support and maintenance.

5.What’s your warranty ?

One-stop service: one-stop service from production to shipment. Quality: A professional engineering team strictly controls product quality. Productivity: Fully automatic equipment can firmly support your bulk orders. Build your ideas: Any custom designs you have are welcome.

6.What services can we provide?

HangZhou CHINAMFG Motor Co., Ltd. is a professional Micro Pumps and solenoid valves manufacturer. Passed ISO 9001, (EU)2015/863, EC1907/2006 quality system. With a talented design team releasing original designs.

7. Why should you buy from us not from other suppliers? HangZhou CHINAMFG Motor Co., Ltd. is a professional Micro Pumps and solenoid valves manufacturer. Passed ISO 9001, (EU)2015/863, EC1907/2006 quality system. With a talented design team releasing original designs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Timely |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil Free |

| Structure: | Reciprocating Vacuum Pump |

| Exhauster Method: | Reciprocating Diaphragm Motion |

| Vacuum Degree: | Vacuum |

| Samples: |

US$ 4/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used for Vacuum Furnaces?

Yes, vacuum pumps can be used for vacuum furnaces. Here’s a detailed explanation:

Vacuum furnaces are specialized heating systems used in various industries for heat treatment processes that require controlled environments with low or no atmospheric pressure. Vacuum pumps play a crucial role in creating and maintaining the vacuum conditions necessary for the operation of vacuum furnaces.

Here are some key points regarding the use of vacuum pumps in vacuum furnaces:

1. Vacuum Creation: Vacuum pumps are used to evacuate the furnace chamber, creating a low-pressure or near-vacuum environment. This is essential for the heat treatment processes carried out in the furnace, as it helps eliminate oxygen and other reactive gases, preventing oxidation or unwanted chemical reactions with the heated materials.

2. Pressure Control: Vacuum pumps provide the means to control and maintain the desired pressure levels within the furnace chamber during the heat treatment process. Precise pressure control is necessary to achieve the desired metallurgical and material property changes during processes such as annealing, brazing, sintering, and hardening.

3. Contamination Prevention: By removing gases and impurities from the furnace chamber, vacuum pumps help prevent contamination of the heated materials. This is particularly important in applications where cleanliness and purity of the processed materials are critical, such as in the aerospace, automotive, and medical industries.

4. Rapid Cooling: Some vacuum furnace systems incorporate rapid cooling capabilities, known as quenching. Vacuum pumps assist in facilitating the rapid cooling process by removing the heat generated during quenching, ensuring efficient cooling and minimizing distortion or other unwanted effects on the treated materials.

5. Process Flexibility: Vacuum pumps provide flexibility in the type of heat treatment processes that can be performed in vacuum furnaces. Different heat treatment techniques, such as vacuum annealing, vacuum brazing, or vacuum carburizing, require specific pressure levels and atmospheric conditions that can be achieved and maintained with the use of vacuum pumps.

6. Vacuum Pump Types: Different types of vacuum pumps can be used in vacuum furnaces, depending on the specific requirements of the heat treatment process. Commonly used vacuum pump technologies include oil-sealed rotary vane pumps, dry screw pumps, diffusion pumps, and cryogenic pumps. The choice of vacuum pump depends on factors such as required vacuum level, pumping speed, reliability, and compatibility with the process gases.

7. Maintenance and Monitoring: Proper maintenance and monitoring of vacuum pumps are essential to ensure their optimal performance and reliability. Regular inspections, lubrication, and replacement of consumables (such as oil or filters) are necessary to maintain the efficiency and longevity of the vacuum pump system.

8. Safety Considerations: Operating vacuum furnaces with vacuum pumps requires adherence to safety protocols. This includes proper handling of potentially hazardous gases or chemicals used in the heat treatment processes, as well as following safety guidelines for operating and maintaining the vacuum pump system.

Overall, vacuum pumps are integral components of vacuum furnaces, enabling the creation and maintenance of the required vacuum conditions for precise and controlled heat treatment processes. They contribute to the quality, consistency, and efficiency of the heat treatment operations performed in vacuum furnaces across a wide range of industries.

Can Vacuum Pumps Be Used for Leak Detection?

Yes, vacuum pumps can be used for leak detection purposes. Here’s a detailed explanation:

Leak detection is a critical task in various industries, including manufacturing, automotive, aerospace, and HVAC. It involves identifying and locating leaks in a system or component that may result in the loss of fluids, gases, or pressure. Vacuum pumps can play a significant role in leak detection processes by creating a low-pressure environment and facilitating the detection of leaks through various methods.

Here are some ways in which vacuum pumps can be used for leak detection:

1. Vacuum Decay Method: The vacuum decay method is a common technique used for leak detection. It involves creating a vacuum in a sealed system or component using a vacuum pump and monitoring the pressure change over time. If there is a leak present, the pressure will gradually increase due to the ingress of air or gas. By measuring the rate of pressure rise, the location and size of the leak can be estimated. Vacuum pumps are used to evacuate the system and establish the initial vacuum required for the test.

2. Bubble Testing: Bubble testing is a simple and visual method for detecting leaks. In this method, the component or system being tested is pressurized with a gas, and then immersed in a liquid, typically soapy water. If there is a leak, the gas escaping from the component will form bubbles in the liquid, indicating the presence and location of the leak. Vacuum pumps can be used to create a pressure differential that forces gas out of the leak, making it easier to detect the bubbles.

3. Helium Leak Detection: Helium leak detection is a highly sensitive method used to locate extremely small leaks. Helium, being a small atom, can easily penetrate small openings and leaks. In this method, the system or component is pressurized with helium gas, and a vacuum pump is used to evacuate the surrounding area. A helium leak detector is then used to sniff or scan the area for the presence of helium, indicating the location of the leak. Vacuum pumps are essential for creating the low-pressure environment required for this method and ensuring accurate detection.

4. Pressure Change Testing: Vacuum pumps can also be used in pressure change testing for leak detection. This method involves pressurizing a system or component and then isolating it from the pressure source. The pressure is monitored over time, and any significant pressure drop indicates the presence of a leak. Vacuum pumps can be used to evacuate the system after pressurization, returning it to atmospheric pressure for comparison or retesting.

5. Mass Spectrometer Leak Detection: Mass spectrometer leak detection is a highly sensitive and precise method used to identify and quantify leaks. It involves introducing a tracer gas, usually helium, into the system or component being tested. A vacuum pump is used to evacuate the surrounding area, and a mass spectrometer is employed to analyze the gas samples for the presence of the tracer gas. This method allows for accurate detection and quantification of leaks down to very low levels. Vacuum pumps are crucial for creating the necessary vacuum conditions and ensuring reliable results.

In summary, vacuum pumps can be effectively used for leak detection purposes. They facilitate various leak detection methods such as vacuum decay, bubble testing, helium leak detection, pressure change testing, and mass spectrometer leak detection. Vacuum pumps create the required low-pressure environment, assist in evacuating the system or component being tested, and enable accurate and reliable leak detection. The choice of vacuum pump depends on the specific requirements of the leak detection method and the sensitivity needed for the application.

How Are Vacuum Pumps Different from Air Compressors?

Vacuum pumps and air compressors are both mechanical devices used to manipulate air and gas, but they serve opposite purposes. Here’s a detailed explanation of their differences:

1. Function:

– Vacuum Pumps: Vacuum pumps are designed to remove or reduce the pressure within a closed system, creating a vacuum or low-pressure environment. They extract air or gas from a chamber, creating suction or negative pressure.

– Air Compressors: Air compressors, on the other hand, are used to increase the pressure of air or gas. They take in ambient air or gas and compress it, resulting in higher pressure and a compacted volume of air or gas.

2. Pressure Range:

– Vacuum Pumps: Vacuum pumps are capable of generating pressures below atmospheric pressure or absolute zero pressure. The pressure range typically extends into the negative range, expressed in units such as torr or pascal.

– Air Compressors: Air compressors, on the contrary, operate in the positive pressure range. They increase the pressure above atmospheric pressure, typically measured in units like pounds per square inch (psi) or bar.

3. Applications:

– Vacuum Pumps: Vacuum pumps have various applications where the creation of a vacuum or low-pressure environment is required. They are used in processes such as vacuum distillation, vacuum drying, vacuum packaging, and vacuum filtration. They are also essential in scientific research, semiconductor manufacturing, medical suction devices, and many other industries.

– Air Compressors: Air compressors find applications where compressed air or gas at high pressure is needed. They are used in pneumatic tools, manufacturing processes, air conditioning systems, power generation, and inflating tires. Compressed air is versatile and can be employed in numerous industrial and commercial applications.

4. Design and Mechanism:

– Vacuum Pumps: Vacuum pumps are designed to create a vacuum by removing air or gas from a closed system. They may use mechanisms such as positive displacement, entrapment, or momentum transfer to achieve the desired vacuum level. Examples of vacuum pump types include rotary vane pumps, diaphragm pumps, and diffusion pumps.

– Air Compressors: Air compressors are engineered to compress air or gas, increasing its pressure and decreasing its volume. They use mechanisms like reciprocating pistons, rotary screws, or centrifugal force to compress the air or gas. Common types of air compressors include reciprocating compressors, rotary screw compressors, and centrifugal compressors.

5. Direction of Air/Gas Flow:

– Vacuum Pumps: Vacuum pumps draw air or gas into the pump and then expel it from the system, creating a vacuum within the chamber or system being evacuated.

– Air Compressors: Air compressors take in ambient air or gas and compress it, increasing its pressure and storing it in a tank or delivering it directly to the desired application.

While vacuum pumps and air compressors have different functions and operate under distinct pressure ranges, they are both vital in various industries and applications. Vacuum pumps create and maintain a vacuum or low-pressure environment, while air compressors compress air or gas to higher pressures for different uses and processes.

editor by Dream 2024-05-17

China Hot selling Disposable Elastomeric Vacuum Pump for Resin Vacuum Infusion Top Syringe Pump vacuum pump ac system

Product Description

disposable elastomeric vacuum pump for resin vacuum infusion top syringe pump

Product Description

|

pecial Function |

|

|

Keep-Vein-Open (KVO): |

After finishing predetermined infusion volume, to prevent the formation of thrombus, continue infusion with preset minimum rate 0.1ml/h (setted). |

|

Power Supply Switching Function: |

When the AC power supply is off, it will automatically switch to internal battery power supply and prompt at the same time. When AC is switched on, it is automatically converted back to AC supply. |

|

Repeat Alarm Function: |

After the operator presses the “” key, if the reason causing the alarm has be untreated for about 2 minutes, the alarm will sound again to alert the operator to solve the problem. |

|

Data Memory Function: |

Save the last setting of sound volume level, brand and occlusion pressure level, to prepare for the next use. The longest memory time is 5 years. |

|

Battery Protection Alarm: |

In order to protect the battery and ensure infusion safety, there are different levels of acousto-optic prompts when the electric quantity of the battery is changing from close to depletion to almost depleted. |

|

Move: |

When user tries to remove or take away the syringe,give move alarm. |

|

High Flow Safety Confirm: |

In order to ensure infusion safety, when the flow rate is greater than 300ml/h (or equivalent), the device will prompt user to confirm again, and will not carry out infusion before confirmation. |

Company Profile

FAQ

-

How to buy your products ?Do you have distributor in our country?

You can buy the products from our company directly.Normally the procedure is:Sign the contact ,payment byT/T, contact the shipping company to delivery the goods to your country.

-

What is the warranty?

The free warranty is 1 year from the day of Commissioning qualified.

-

Can we visit your country ?

Of course,we will prepare for everything in advance if it is necessary .Generally,it is require that customers must have build agency relationship or business relationship with our company.

-

How long is the validity of quotation?

Generally,our price is valid within 1 month from the date of quotation .The price will be adjusted appropriately according to the price fluctuation of raw material and changes in market .

-

Do you have the CE certificate ?

Yes, most of our products have the CE certificate.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, FDA, EEC, ISO13485 |

|---|---|

| Scale: | Small |

| Type: | Injection Pump |

| Kvo: | 0.1ml/H |

| Electric Shock Protection: | Type CF |

| Syringe Size: | 30/35ml,50/60ml |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the cost considerations when purchasing or installing small vacuum pumps?

When purchasing and installing small vacuum pumps, there are several cost considerations to keep in mind. These costs can vary based on factors such as the type of pump, application, and installation requirements. Here are key cost considerations:

1. Initial Purchase Cost:

The initial purchase cost of the vacuum pump is a significant factor. Different types of small vacuum pumps come with varying price tags. For example, diaphragm and rotary vane pumps are generally more affordable than high-end scroll pumps or specialized pumps for specific applications.

2. Pump Type:

The type of vacuum pump you choose will impact the cost. Oil-free pumps may be more expensive upfront but can reduce long-term maintenance and oil-related costs.

3. Application Requirements:

The specific requirements of your application can affect costs. For instance, if your application demands a high vacuum level or precise control, you may need a more advanced and costly pump.

4. Maintenance Costs:

Consider the long-term maintenance costs of the pump. Oil-lubricated pumps require regular oil changes and maintenance, which can add to the overall cost of ownership. Oil-free pumps generally have lower maintenance costs.

5. Installation Expenses:

Installation costs may include labor, materials, and any necessary modifications to your equipment or facility. Some pumps may require specialized installation, especially in industrial or laboratory settings.

6. Operating Costs:

Factor in the ongoing operating costs, such as electricity consumption. Energy-efficient pumps may have lower operational expenses over time.

7. Warranty and Service:

Check the manufacturer’s warranty and the availability of service and spare parts. A longer warranty can provide cost savings by reducing repair expenses.

8. Life Cycle Costs:

Consider the total cost of ownership over the pump’s expected lifespan. A higher upfront cost may be justified if it results in lower overall operating and maintenance costs.

9. Energy Efficiency:

Energy-efficient pumps may have a higher initial cost but can lead to significant savings in energy bills over time.

10. Regulatory Compliance:

Some industries or applications may require compliance with specific regulations or safety standards, which could add costs related to compliance testing and certification.

11. Customization:

If your application requires customized features or configurations, be prepared for potential customization costs.

12. Spare Parts and Accessories:

Consider the availability and cost of spare parts and accessories, as well as any additional components you may need for your specific application.

It’s essential to perform a thorough cost analysis that takes into account both the initial purchase cost and the long-term operating and maintenance expenses. This analysis will help you make an informed decision when selecting a small vacuum pump that aligns with your budget and application requirements.

Additionally, consult with manufacturers or suppliers to obtain detailed cost estimates and explore any available financing options or discounts that may apply to your purchase.

Can you describe the typical power sources for small vacuum pumps?

Small vacuum pumps can be powered by various sources, depending on their design, size, and intended applications. Here are the typical power sources for small vacuum pumps:

1. Electric Power:

Most small vacuum pumps are electrically powered and use standard alternating current (AC) or direct current (DC) sources. Electric vacuum pumps are versatile and widely used in laboratory equipment, industrial processes, and portable devices. They can be plugged into wall outlets or connected to DC power sources such as batteries or power supplies.

2. Battery Power:

Portable and handheld devices often incorporate battery-powered small vacuum pumps. These pumps are ideal for applications where mobility is crucial, such as fieldwork, medical instruments, and handheld vacuum aspirators. Batteries can be rechargeable or disposable, depending on the device’s requirements.

3. Compressed Air:

In some applications, small vacuum pumps are driven by compressed air or other gases. These pumps are known as pneumatic or air-operated vacuum pumps. They are commonly used in industrial automation, vacuum gripping systems, and manufacturing processes where compressed air is readily available.

4. Hydraulic Power:

In specialized applications, small vacuum pumps can be hydraulically powered. These pumps are often used in systems where hydraulic power sources are already in use. They are less common than electric or pneumatic options but find application in specific industries like automotive manufacturing.

5. Solar Power:

In remote or off-grid locations, small vacuum pumps can be powered by solar panels and photovoltaic systems. Solar-powered vacuum pumps are environmentally friendly and energy-efficient, making them suitable for sustainable and remote applications.

6. Hand Cranks:

For ultra-portable and emergency situations, some small vacuum pumps can be hand-operated using a manual hand crank. These pumps are typically compact and lightweight, making them suitable for backup or low-volume vacuum needs.

7. Engine-Driven:

In certain industrial and automotive applications, small vacuum pumps can be driven by an internal combustion engine. These pumps are commonly used in power brake boosters and emission control systems in vehicles.

The choice of power source for a small vacuum pump depends on factors such as the application’s mobility requirements, availability of power sources, energy efficiency goals, and environmental considerations. Manufacturers design vacuum pumps to be compatible with various power sources to meet diverse application needs.

Can you explain the different types of small vacuum pumps available in the market?

Certainly, there are several types of small vacuum pumps available in the market, each with unique working principles and applications. Here are some of the most common types:

1. Diaphragm Vacuum Pumps:

Diaphragm vacuum pumps use a flexible diaphragm that moves up and down to create suction. These pumps are oil-free, making them ideal for applications where contamination from lubricants is a concern, such as in laboratories. They are commonly used in vacuum filtration, sample concentration, and scientific research.

2. Rotary Vane Vacuum Pumps:

Rotary vane vacuum pumps operate by using vanes that rotate inside a cylindrical chamber. As the vanes move, they create a vacuum by trapping and compressing gas. These pumps are known for their high efficiency and reliability. They are used in applications like rotary evaporation, HVAC systems, and industrial processes.

3. Piston (Reciprocating) Vacuum Pumps:

Piston vacuum pumps use a piston-cylinder arrangement to create a vacuum. They are often found in smaller, portable units and are suitable for applications requiring intermittent or continuous vacuum, such as refrigeration evacuation, air sampling, and medical devices.

4. Scroll Vacuum Pumps:

Scroll vacuum pumps consist of two interleaved spiral scrolls that move in opposite directions. This design generates a series of crescent-shaped pockets, trapping and compressing gas as they move. Scroll pumps are known for their quiet operation and are used in applications like semiconductor manufacturing, analytical instruments, and vacuum ovens.

5. Venturi Vacuum Pumps:

Venturi vacuum pumps operate using the Venturi effect, where a high-speed fluid (usually air or gas) creates a vacuum when passing through a constriction. These pumps are simple and compact, making them suitable for portable and lightweight applications like vacuum pick-and-place systems and vacuum grippers.

6. Turbomolecular Vacuum Pumps:

Turbomolecular vacuum pumps are high-speed pumps that use rotating blades to capture and accelerate gas molecules out of the vacuum chamber. They are capable of achieving very high vacuum levels and are used in ultra-high vacuum applications, such as electron microscopy, mass spectrometry, and semiconductor manufacturing.

Choosing the right type of small vacuum pump depends on factors such as the required vacuum level, flow rate, contamination sensitivity, and application-specific requirements. It’s essential to consider these factors when selecting a vacuum pump to ensure it meets your needs effectively.

editor by Dream 2024-05-17

China high quality 2xz-2 2xz-4 Oil Sealed High Pressure Vane Rotary Vacuum Pump vacuum pump ac

Product Description

Product Description

2XZ Series Rotary Vane Vacuum Pump

Overview

2XZ series vacuum pump has bipolar direct connecting structure, the working performance Is consisted of high pressure and low pressure grades. The inhalant hole Connects with vacuum equipment, the air in the container will be inhaled and exhausted Greatly while running.

This series of pumps are elementary equipment for pumping air from sealed vassels. It can be used alone, also can be used as the fore pump, process pump or titanium pump of booster pump, diffusion pump, and molecular pump. The pumps are also used in making electrical vacuum cases, vacuum jointing, printing, photoengraving, food packaging, vacuum forming, refrigeration equipment repair and instruments or a set of equipments in laboratory, It is widely used in aerospace, semiconductor , coating , food packaging,drying machines, refrigeration equipment, scientific research, medical treatment, electronics, chemicals, medicine and laboratory or laboratory of universities and colleges.

Features

a. Small volume, low weight and low noise

b. Equipped with gas ballast valve to pump a little water vapor.

c. Equipped with oil anti-suck back device.

d. 2XZ-2 with small caliber, 2XZ-4 pump with vacuum drying oven, freezing dry machine and printing machine.

e.Equipped with small caliber transforming joints and KF joints.

Product Parameters

|

Parameters/Model |

2XZ-0.25 |

2XZ-0.5 |

2XZ-1 |

2XZ-2 |

2XZ-4 |

|

|

Pumping speedm3/h(L/S) |

50(HZ) |

0.9(0.25) |

1.8(0.5) |

3.6(1) |

7.2(2) |

14.4(4) |

|

60(HZ) |

1.1(0.3) |

2.1(0.6) |

4.3(1.2) |

8.6(2.4) |

17.2(4.8) |

|

|

Ultimate pressure (Pa) |

Partial pressure |

≤6×10-1 |

≤6×10-2 |

≤6×10-2 |

≤6×10-2 |

≤6×10-2 |

|

Total pressure |

≤6.5 |

≤1.33 |

≤1.33 |

≤1.33 |

≤1.33 |

|

|

Rotary speed(r/min) |

50(HZ) |

1400 |

1400 |

1400 |

1400 |

1400 |

|

60(HZ) |

1720 |

1720 |

1720 |

1720 |

1720 |

|

|

Moter power(kw) |

0.12 |

0.18 |

0.25 |

0.37 |

0.55 |

|

|

Voltage(V) |

220 |

220/380 |

220/380 |

220/380 |

220/380 |

|

|

Inlet diam(O.D.)(mm) |

φ15 |

φ20 |

φ20 |

φ30 |

φ30 |

|

|

Noise level(dBA) |

63 |

65 |

65 |

68 |

68 |

|

|

Oil capacity(L) |

0.5 |

0.6 |

0.7 |

1 |

1.2 |

|

|

Dimensions(mm) |

403×130×240 |

447×168×260 |

469×168×260 |

514×168×282 |

565×168×282 |

|

|

Gross weight/Net weight(Kg) |

16/15 |

17/16 |

18/17 |

22/20 |

24/22 |

|

Detailed Photos

Packaging & Shipping

Packing Details : One pump in One plywood case

Delivery Details : 30 days after order confirmation

Standard package without original wood, no fumigation needed.

Company Profile

ZheZheJiang oto Pump Industrial Co., Ltd. is a professional pump manufacturer integrating R&D, manufacturing, sales and service as a whole, which has been certified by ISO9001 international quality management system.

Located in Xihu (West Lake) Dis.a Industrial Park, ZheJiang , CHINAMFG Pump Industrial possesses 2 manufacturing bases in ZheJiang and ZHangZhoug. Since our inception, CHINAMFG Pump Industrial has been committed to the innovation and development of various pumps. Our leading products include self-priming trash pump, centrifugal pump, submersible pump, diaphragm pump, vacuum pump, diesel pump, fire pump, etc.

FAQ

Q: Can I chat with you online? What is your company official website?

Q: What type of company CHINAMFG is?

A: CHINAMFG is a manufacture and trading company, has factories in ZheJiang and ZHangZhoug, with export and import license.

Q: What kinds of pumps do you supply?

A: Our products including self-priming trash pump, centrifugal pump, diaphragm pump, submersible pump, chemical pump, oil pump, diesel pump, fire fighting pump, etc.

Q: What is your payment terms?

A: Alibaba Trade Assurance, Western Union, Paypal, T/T, L/C, etc.

Q: Can you provide OEM, ODM service?

A: Yes. We have factories in ZheJiang and ZHangZhoug, we can make products according to your requirements.

Q: Why should we buy from you?

A: We are committed to provide best quality products at minimum delivery time and competitive price. We believe this is what customer wants. We are satified until customers are.

Q: What is your warranty period?

A: We provide 1 year of unconditional warranty on our products for the manufacturing defects.

Q: What about delivery time?

A: Normally our production time is within 2 weeks. Please confirm before order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Acting Form: | Single-Acting |

| Type: | Centrifugal Pump |

| Displacement: | Variable Pump |

| Performance: | No Leak |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Where can individuals or businesses source small vacuum pumps for various applications?

Individuals and businesses looking to source small vacuum pumps for a wide range of applications have several options to consider. Here are common sources for acquiring small vacuum pumps:

1. Manufacturers and Authorized Dealers:

Contacting the manufacturers directly or their authorized dealers is often a reliable way to purchase small vacuum pumps. Manufacturers typically offer a wide selection of models and provide technical support. Authorized dealers can assist with product selection and may offer competitive pricing.

2. Industrial Suppliers:

Industrial supply companies and distributors often carry a variety of vacuum pumps. These suppliers cater to a range of industries, including manufacturing, research, and laboratories. They can provide competitive pricing and may offer bulk purchase discounts.

3. Laboratory Equipment Suppliers:

For those seeking vacuum pumps for laboratory or scientific applications, specialized laboratory equipment suppliers are a valuable resource. They offer pumps designed for precise and controlled vacuum needs.

4. Online Marketplaces:

Online marketplaces like Amazon, eBay, and Alibaba feature a wide array of small vacuum pumps from various manufacturers and sellers. Buyers can compare prices, read reviews, and often find both new and used pumps.

5. HVAC and Refrigeration Suppliers:

Heating, ventilation, air conditioning, and refrigeration (HVAC/R) suppliers may carry vacuum pumps suitable for HVAC system maintenance and refrigeration applications. These suppliers are often found locally.

6. Scientific and Research Institutions:

Scientific and research institutions occasionally sell surplus equipment, including vacuum pumps, through online auctions or specialized surplus equipment vendors.

7. Rental Services:

For short-term or occasional use, renting small vacuum pumps can be a cost-effective option. Equipment rental companies may offer various pump types for temporary applications.

8. Online Manufacturer Websites:

Visiting the official websites of vacuum pump manufacturers provides access to comprehensive product information, specifications, and contact details for sales and support.

9. Trade Shows and Exhibitions:

Attending industry-specific trade shows, exhibitions, and conferences can be an excellent opportunity to connect with manufacturers, distributors, and suppliers in person. It allows for hands-on product evaluation and networking.

10. Classified Ads and Auctions:

Classified advertisement websites and auction platforms may feature used vacuum pumps for sale. Buyers should exercise caution and thoroughly assess the condition of used equipment.

When sourcing small vacuum pumps, individuals and businesses should consider factors such as the pump’s specifications, warranty, customer support, and the reputation of the supplier or seller. It’s essential to choose a source that aligns with the specific requirements of the application and ensures the reliability and performance of the vacuum pump.

What factors should one consider when choosing a small vacuum pump for a specific task?

Choosing the right small vacuum pump for a specific task is essential to ensure optimal performance and efficiency. Several factors should be taken into account when making your selection:

1. Vacuum Level Requirements:

Determine the required vacuum level for your application. Some tasks may require a high vacuum level, while others can be accomplished with a lower vacuum. The pump’s ultimate vacuum capability should match your needs.

2. Flow Rate:

Consider the volume of gas or air that needs to be evacuated or processed per unit of time. Choose a pump with an adequate flow rate to meet your application’s requirements. Insufficient flow can lead to slow or inefficient processes.

3. Type of Gas:

Identify the type of gas or vapor you will be handling. Some gases may be corrosive, reactive, or incompatible with certain pump materials. Ensure that the pump you select is compatible with the gases involved in your task.

4. Contamination Sensitivity:

If your application demands a clean and contamination-free vacuum environment, consider pumps that operate without oil lubrication, such as diaphragm or scroll pumps. These pumps are suitable for applications like analytical instruments and cleanroom environments.

5. Power Source:

Determine the available power source for your pump. Small vacuum pumps can be electric, battery-powered, pneumatic, or even hand-operated. Choose a power source that aligns with your application’s requirements and availability.

6. Portability:

If mobility is essential, opt for a compact and lightweight vacuum pump. Battery-powered or pneumatic pumps are often chosen for portable applications. Consider the size and weight of the pump relative to the device or equipment it will be integrated into.

7. Noise Level:

Assess the noise level generated by the pump. Some small vacuum pumps operate quietly, which is advantageous in noise-sensitive environments like laboratories and medical facilities. Low-noise pumps are also suitable for handheld devices.

8. Maintenance Requirements:

Consider the maintenance needs of the pump. Some pumps have simpler designs and require less frequent servicing. Evaluate factors such as filter replacement, lubrication, and ease of access for maintenance tasks.

9. Cost and Budget:

Take into account your budget constraints. Small vacuum pumps come in a range of price points, so choose one that offers the best balance between performance and cost while meeting your specific requirements.

10. Environmental Considerations:

Consider environmental factors, especially if your application is in a sensitive or regulated area. Assess energy efficiency, emissions, and any environmental certifications or standards that the pump may need to meet.

11. Application Specifics:

Finally, closely examine the unique requirements of your specific task. Each application may have its own considerations, so tailor your choice to suit the precise demands of your project or process.

By carefully evaluating these factors, you can select the most appropriate small vacuum pump for your specific task, ensuring that it performs efficiently and effectively.

What are the advantages of using a small vacuum pump in specific applications?

Small vacuum pumps offer various advantages in specific applications across multiple industries. These advantages make them valuable tools for achieving specific tasks efficiently. Here are some key advantages:

1. Portability:

Small vacuum pumps are compact and lightweight, making them easy to transport and use in various locations. Their portability is especially beneficial for fieldwork, mobile applications, and situations where mobility is essential.

2. Precision and Control:

Small vacuum pumps provide precise control over the vacuum level, allowing for accurate and controlled processes. This level of control is crucial in scientific research, medical procedures, and manufacturing applications requiring fine-tuned vacuum conditions.

3. Oil-Free Operation:

Many small vacuum pumps, such as diaphragm pumps, operate without the need for oil lubrication. This oil-free operation is essential in applications where oil contamination is undesirable, such as in laboratories and cleanroom environments.

4. Low Maintenance:

Compared to larger industrial vacuum systems, small vacuum pumps often have simpler maintenance requirements. They are designed for ease of use and may require less frequent servicing, reducing downtime and maintenance costs.

5. Energy Efficiency:

Small vacuum pumps are energy-efficient, especially when equipped with features like variable speed drives (VSDs). VSDs allow the pump to adjust its speed based on demand, minimizing energy consumption and reducing operational costs.

6. Quiet Operation:

Some small vacuum pumps, such as scroll pumps and diaphragm pumps, operate quietly. This characteristic is advantageous in environments where noise levels need to be minimized, such as in laboratories, medical facilities, and offices.

7. Versatility:

Small vacuum pumps can be used in a wide range of applications, including vacuum filtration, rotary evaporation, sample concentration, and air sampling. Their versatility makes them suitable for diverse industries, from pharmaceuticals to electronics manufacturing.

8. Cost-Effectiveness:

Small vacuum pumps are often more cost-effective than larger industrial vacuum systems. They offer a balance between performance and affordability, making them accessible to a broad range of users and applications.

It’s important to note that the advantages of using small vacuum pumps are application-specific. To maximize the benefits, it’s essential to select the right type of pump that matches the requirements and constraints of the specific application.

editor by Dream 2024-05-17

China Best Sales 2.0L Petrol Brake Vacuum Pump for Land Rover Freelander 2 Range Rover Evoque Discovery Sport CZPT 724807650 Lr025601 Lr047384 vacuum pump diy

Product Description

| Product Information | |

| Product name | Vacuum Pump |

| OEM | 724807650 LR571601 LR57184 |

| Warranty | 1 year |

| Certifications | CE |

| Condition | Brand-new |

| Appliction | For LAND ROVER |

| Brand Name | ZOOMKEY |

| Place of Origin | ZheJiang , China |

| Quality | High-performance |

| Related Products |

| Company Profile |

| Our advantages |

One-stop solution for auto parts

ODM and OEM customized

with 12 months-24 months warranty

high quality, professional service

Zoomrich is a company specialized in distribution and service for CZPT car parts,Especially in Volkswagen, Audi, Mercedes-Benz, BMW, Por sche,Jaguar,Land-Rover autoparts.Our business includes temperature control system,suspension parts, engine parts, electrical parts, and some other product lines.We are based in ZheJiang , and cooperate with many international first-line brands in order to meet the customer’s choice of diversity. Based on 12 years of experience,We accumulated a lot of factory resources and build a long-term cooperation in China which include OEM factory,OES resources,IAM factory verified by International famous brand.

About Us

CZPT electronic commerce(ZheJiang )Co.Ltd.is specialized in serving the German car system. The products are suitable for Mercedes-Benz, BMW,Volkswagen imported and other luxury cars. It covers auto engine system, auto transmission system, auto covering system, auto temperature control system,auto suspension and steering system, auto electronic system and so on.

With years of experience in the market of China in auto parts field ,our products have been exported to all over the world simultaneously.We have integrate the R&D,manufacture and trade. Supportina ODM

&OEM customized,and strict support confidentiality of customer brands and property rights. We will try our best to cooperation with you to establish a CZPT relationship.

| AFQ |

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to Western Europe(20.00%),Domestic Market(20.00%),North America(10.00%),South America(10.00%),Eastern Europe(10.00%),Northern Europe(10.00%),Southeast Asia(5.00%),Africa(5.00%),Mid East(5.00%),Eastern Asia(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

camshaft adjuster,headlamp accessories,cylinder head cover,shock absorber,tensioner

4. why should you buy from us not from other suppliers?

One-stop solution for auto parts ODM and OEM customized with 12 months-24 months warranty

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,PayPal,Western Union,Cash;

Language Spoken:English,Chinese

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Months |

|---|---|

| Warranty: | 1 Year |

| Product Name: | Vacuum Pump |

| Appliction: | for Land Rover |

| Package: | Carton Box |

| Quality: | High-Performance |

| Samples: |

US$ 28/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How to install a vacuum pump

A vacuum pump creates a relative vacuum within a sealed volume by drawing gas molecules from the sealed volume. Vacuum pumps can be used in a variety of industrial applications. They also offer various lubrication options. If you are considering purchasing, please understand its functions and features before purchasing.

How it works

The working principle of a vacuum pump is called gas transfer. The principle can be further divided into two basic categories: positive displacement and momentum transfer. At high pressure and moderate vacuum, gas molecules collide and move and create a viscous flow. At higher vacuum levels, gas molecules separate to create molecular or transitional flows.

Another principle of vacuum pumps is fluid-tightness. There are two main types of seals: rotary seals and screw seals. Rotary seals prevent liquid leakage, while screw seals only allow liquids to flow out at higher pressures. Some pumps may not use the third seal.

The flow rate of the vacuum pump determines the machine’s ability to pump a certain amount of material. A higher pumping speed will shorten the drain time. Therefore, the mass flow of the vacuum pump must be carefully considered. The speed and type of vacuum must also be considered.

The working principle of a vacuum pump is to push gas molecules from a high-pressure state to a low-pressure state. This creates a partial vacuum. There are many different types of vacuum pumps, each with different functions. Some are mechanical, some are chemical. In either case, their function is the same: to create a partial or complete vacuum. Vacuum pumps use a variety of technologies and are sized according to the application. Proper sizing is critical for optimum efficiency.

Gas transfer pumps use the same principles as vacuum pumps but use different technology. One of the earliest examples is the Archimedes spiral. Its structure consists of a single screw inside a hollow cylinder. More modern designs use double or triple screws. The rotation of the screw causes gas molecules to be trapped in the cavity between the screw and the housing. The fluid is then discharged at slightly above atmospheric pressure. This difference is called the compression ratio.

Another type of vacuum pump is a diffusion pump. Its main use is industrial vacuum processing. It is used in applications such as mass spectrometry, nanotechnology and analytical instrumentation. These pumps are generally inexpensive to purchase and operate.

Apply

Vacuum pumps are essential for many scientific and industrial processes. They are used in the production of vacuum tubes, CRTs, lamps and semiconductor processing. They can also be used to support mechanical equipment. For example, they can be mounted on the engine of a motor vehicle. Likewise, they can be used to power hydraulic components of aircraft. Among other uses, the vacuum pump helps calibrate the gyroscope.

Vacuum pumps are widely used in the pharmaceutical industry and are one of the largest users of this technology. They help deal with hazardous materials and eliminate waste quickly. They are also used in power jets, dump fuel tanks and rear doors, among others. However, they are sensitive to contamination and should only be used in environments where leaks can be prevented. Therefore, choosing the right fluid for the application is very important.

The most popular type of vacuum pump is the rotary vane pump. These pumps are known for their high pumping speed and low pressure. Their efficient pumping capacity allows them to reach pressures below 10-6 bar. Additionally, they are usually oil-sealed and have excellent vacuuming capabilities.

Vacuum pumps are often used to remove air from closed systems. They create a vacuum by reducing the density of the air in the compressed space. This is done by using the mechanical force energy generated by the rotating shaft. When the pump is under pressure, it converts this energy into pneumatic power. When the pressure is different, the energy produced depends on the volume of the gas and the pressure difference between the inner and outer atmospheres.

Vacuum pumps are also used in the manufacture of solar cells. They are used in the manufacture of solar cells, including ingot casting processes as well as cell and module processes. The design of the vacuum system plays an important role in reducing the cost of the process, thus making it profitable. Due to their low maintenance costs, they are an invaluable tool for making solar cells.

Vacuum pumps are widely used in many applications. In addition to industrial and research uses, they are also used in water remediation.

Oil Lubrication Option

Vacuum pumps are available in a variety of oil lubrication options. Choosing the right lubricant can help protect your vacuum pump and maximize its performance. Different base oils may contain different additives, such as antioxidants, and some contain additional additives for specific purposes. You should choose an oil with the right concentration of these additives for optimal lubrication of your vacuum pump.

Vacuum pumps are usually lubricated with paraffinic mineral oil. However, this type of lubricant evaporates as the temperature increases. To minimize evaporative losses, choose a lubricant with low vapor pressure. Also, you should choose lubricants that are resistant to extreme temperatures. Extreme temperatures can put extra stress on the oil and can even significantly shorten the life of the oil.

In terms of viscosity, synthetic oils are the best choice for vacuum pumps. These types of oils are designed to resist gas dissolution and are more resistant to corrosion. Therefore, synthetic oils are ideal for handling aggressive substances. Whether or not your pump needs lubrication, choosing a quality product is important.

The vacuum pump oil should be changed periodically according to the manufacturer’s recommendations. If you use a filter, you should also change the oil as soon as the filter reaches the end of its life. Unplanned oil changes will eventually cause the vacuum pump to not reach its maximum vacuum capacity.

You can buy vacuum pump oil from vacuum pump manufacturers or other suppliers. These options are available in a variety of sizes, and labels can be customized. The oil should be designed for the pump. However, you should check the manufacturer’s recommendations to avoid buying the wrong type.

If you choose to use a synthetic oil, it is important to use a good quality oil. It helps the pump work more efficiently and prolong its life.

Install

After choosing a suitable location, the next step is to install the pump. First, place the pump on a flat surface. Then, screw the pump onto the motor body above the check valve. Make sure the accessories are wrapped with sealing tape and secured with screws. The direction of gas inflow and outflow is indicated by arrows on the pump. The direction of rotation around the pump is also shown.

During commissioning, check the operation of each part of the pump. If the pump is equipped with a pipe connection, the pipe should be the same size and shape as the pump flange. Also, make sure that the piping does not cause any pressure drop. In addition, the first three weeks of operation require the installation of protective nets at the suction ports.

When selecting a pump, consider the back pressure of the system. Too much back pressure will affect the capacity of the vacuum pump. Also, check the temperature of the seal. If the temperature is too high, the seal may be damaged. It could also be due to a partially closed valve in the recirculation line or a clogged filter. Circulation pumps and heat exchangers should also be checked for fouling.

The vacuum pump is usually installed in the chassis area of the car. They can be mounted next to the engine or on a lower support frame. They are usually fastened to the bracket using suitable shock absorbers and isolating elements. However, before installing the vacuum pump, be sure to check the vacuum pump’s wiring harness before connecting it to the vehicle.

In many experimental setups, a vacuum pump is essential. However, improperly installed vacuum pumps can expose users to harmful vapors and chemicals. Appropriate plugs and belt guards should be installed to prevent any accidental chemical exposure. It is also important to install a fume hood for the pump.

In most cases, vacuum pumps come with installation manuals and instructions. Some manufacturers even offer start-up assistance if needed.

editor by Dream 2024-05-17

China Hot selling Circulating Water Pump Vacuum Pump Value vacuum pump booster

Product Description

Circulating Water Pump Vacuum Pump Value

Product Description

The circulating water vacuum pump is a laboratory vacuum generator that uses a water jet to generate a vacuum. This machine is used to provide vacuum conditions for the process of evaporation, distillation, crystallization, drying, sublimation, filtration, degassing, decompression, and so on, particularly be suitable for labs and small-scale tests in industries such as universities and colleges, scientific research institutes, chemical industry, pharmacy, biochemistry, foodstuff, pesticide, agricultural engineering, biological engineering.

Product Parameters

| Model | SHZ-D | SHZ-D four-meter, four tap |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The machine Performance | Power(W) | 180 | 370 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Voltage(V/Hz) | 220/50 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flow(L/min) | 60 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lift(m) | 8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Body material | Anti-corrosion/1Cr18 | Anti-corrosion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The machine performance | Max. pressure (M Pa) | 0.098 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sucking rate for single tap(L/min) | 10 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantity of tap (Pcs) | 2 | 4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tank capacity(L) | 15 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimension(mm) | 4362 Main Markets: Central America, Mid East, Oceania, Africa, South America

Packaging & Shipping

Packaging:

FAQ 1. What’s the minimum order quantity?

2. What kind of payment terms do you accept? 3. How will you deliver these goods? 4. How will we package glass equipment be? 5. Can you accept OEM terms? 6. How to choose suitable equipment?

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Vacuum Pumps Be Used in the Aerospace Sector?Vacuum pumps indeed have various applications in the aerospace sector. Here’s a detailed explanation: Vacuum pumps play a crucial role in several areas of the aerospace industry, supporting various processes and systems. Some of the key applications of vacuum pumps in the aerospace sector include: 1. Space Simulation Chambers: Vacuum pumps are used in space simulation chambers to replicate the low-pressure conditions experienced in outer space. These chambers are utilized for testing and validating the performance and functionality of aerospace components and systems under simulated space conditions. Vacuum pumps create and maintain the necessary vacuum environment within these chambers, allowing engineers and scientists to evaluate the behavior and response of aerospace equipment in space-like conditions. 2. Propellant Management: In space propulsion systems, vacuum pumps are employed for propellant management. They help in the transfer, circulation, and pressurization of propellants, such as liquid rocket fuels or cryogenic fluids, in both launch vehicles and spacecraft. Vacuum pumps assist in creating the required pressure differentials for propellant flow and control, ensuring efficient and reliable operation of propulsion systems. 3. Environmental Control Systems: Vacuum pumps are utilized in the environmental control systems of aircraft and spacecraft. These systems are responsible for maintaining the desired atmospheric conditions, including temperature, humidity, and cabin pressure, to ensure the comfort, safety, and well-being of crew members and passengers. Vacuum pumps are used to regulate and control the cabin pressure, facilitating the circulation of fresh air and maintaining the desired air quality within the aircraft or spacecraft. 4. Satellite Technology: Vacuum pumps find numerous applications in satellite technology. They are used in the fabrication and testing of satellite components, such as sensors, detectors, and electronic devices. Vacuum pumps help create the necessary vacuum conditions for thin film deposition, surface treatment, and testing processes, ensuring the performance and reliability of satellite equipment. Additionally, vacuum pumps are employed in satellite propulsion systems to manage propellants and provide thrust for orbital maneuvers. 5. Avionics and Instrumentation: Vacuum pumps are involved in the production and testing of avionics and instrumentation systems used in aerospace applications. They facilitate processes such as thin film deposition, vacuum encapsulation, and vacuum drying, ensuring the integrity and functionality of electronic components and circuitry. Vacuum pumps are also utilized in vacuum leak testing, where they help create a vacuum environment to detect and locate any leaks in aerospace systems and components. 6. High Altitude Testing: Vacuum pumps are used in high altitude testing facilities to simulate the low-pressure conditions encountered at high altitudes. These testing facilities are employed for evaluating the performance and functionality of aerospace equipment, such as engines, materials, and structures, under simulated high altitude conditions. Vacuum pumps create and control the required low-pressure environment, allowing engineers and researchers to assess the behavior and response of aerospace systems in high altitude scenarios. 7. Rocket Engine Testing: Vacuum pumps are crucial in rocket engine testing facilities. They are utilized to evacuate and maintain the vacuum conditions in engine test chambers or nozzles during rocket engine testing. By creating a vacuum environment, these pumps simulate the conditions experienced by rocket engines in the vacuum of space, enabling accurate testing and evaluation of engine performance, thrust levels, and efficiency. It’s important to note that aerospace applications often require specialized vacuum pumps capable of meeting stringent requirements, such as high reliability, low outgassing, compatibility with propellants or cryogenic fluids, and resistance to extreme temperatures and pressures. In summary, vacuum pumps are extensively used in the aerospace sector for a wide range of applications, including space simulation chambers, propellant management, environmental control systems, satellite technology, avionics and instrumentation, high altitude testing, and rocket engine testing. They contribute to the development, testing, and operation of aerospace equipment, ensuring optimal performance, reliability, and safety.

What Is the Difference Between Dry and Wet Vacuum Pumps?Dry and wet vacuum pumps are two distinct types of pumps that differ in their operating principles and applications. Here’s a detailed explanation of the differences between them: Dry Vacuum Pumps: Dry vacuum pumps operate without the use of any lubricating fluid or sealing water in the pumping chamber. They rely on non-contact mechanisms to create a vacuum. Some common types of dry vacuum pumps include: 1. Rotary Vane Pumps: Rotary vane pumps consist of a rotor with vanes that slide in and out of slots in the rotor. The rotation of the rotor creates chambers that expand and contract, allowing the gas to be pumped. The vanes and the housing are designed to create a seal, preventing gas from flowing back into the pump. Rotary vane pumps are commonly used in laboratories, medical applications, and industrial processes where a medium vacuum level is required. 2. Dry Screw Pumps: Dry screw pumps use two or more intermeshing screws to compress and transport gas. As the screws rotate, the gas is trapped between the threads and transported from the suction side to the discharge side. Dry screw pumps are known for their high pumping speeds, low noise levels, and ability to handle various gases. They are used in applications such as semiconductor manufacturing, chemical processing, and vacuum distillation. 3. Claw Pumps: Claw pumps use two rotors with claw-shaped lobes that rotate in opposite directions. The rotation creates a series of expanding and contracting chambers, enabling gas capture and pumping. Claw pumps are known for their oil-free operation, high pumping speeds, and suitability for handling dry and clean gases. They are commonly used in applications such as automotive manufacturing, food packaging, and environmental technology. Wet Vacuum Pumps: Wet vacuum pumps, also known as liquid ring pumps, operate by using a liquid, typically water, to create a seal and generate a vacuum. The liquid ring serves as both the sealing medium and the working fluid. Wet vacuum pumps are commonly used in applications where a higher level of vacuum is required or when handling corrosive gases. Some key features of wet vacuum pumps include: 1. Liquid Ring Pumps: Liquid ring pumps feature an impeller with blades that rotate eccentrically within a cylindrical casing. As the impeller rotates, the liquid forms a ring against the casing due to centrifugal force. The liquid ring creates a seal, and as the impeller spins, the volume of the gas chamber decreases, leading to the compression and discharge of gas. Liquid ring pumps are known for their ability to handle wet and corrosive gases, making them suitable for applications such as chemical processing, oil refining, and wastewater treatment. 2. Water Jet Pumps: Water jet pumps utilize a jet of high-velocity water to create a vacuum. The water jet entrains gases, and the mixture is then separated in a venturi section, where the water is recirculated, and the gases are discharged. Water jet pumps are commonly used in laboratories and applications where a moderate vacuum level is required. The main differences between dry and wet vacuum pumps can be summarized as follows: 1. Operating Principle: Dry vacuum pumps operate without the need for any sealing fluid, while wet vacuum pumps utilize a liquid ring or water as a sealing and working medium. 2. Lubrication: Dry vacuum pumps do not require lubrication since there is no contact between moving parts, whereas wet vacuum pumps require the presence of a liquid for sealing and lubrication. 3. Applications: Dry vacuum pumps are suitable for applications where a medium vacuum level is required, and oil-free operation is desired. They are commonly used in laboratories, medical settings, and various industrial processes. Wet vacuum pumps, on the other hand, are used when a higher vacuum level is needed or when handling corrosive gases. They find applications in chemical processing, oil refining, and wastewater treatment, among others. It’s important to note that the selection of a vacuum pump depends on specific requirements such as desired vacuum level, gas compatibility, operating conditions, and the nature of the application. In summary, the primary distinction between dry and wet vacuum pumps lies in their operating principles, lubrication requirements, and applications. Dry vacuum pumps operate without any lubricating fluid, while wet vacuum pumps rely on a liquid ring or water for sealing and lubrication. The choice between dry and wet vacuum pumps depends on the specific needs of the application and the desired vacuum level.

Can Vacuum Pumps Be Used in Laboratories?Yes, vacuum pumps are extensively used in laboratories for a wide range of applications. Here’s a detailed explanation: Vacuum pumps are essential tools in laboratory settings as they enable scientists and researchers to create and control vacuum or low-pressure environments. These controlled conditions are crucial for various scientific processes and experiments. Here are some key reasons why vacuum pumps are used in laboratories: 1. Evaporation and Distillation: Vacuum pumps are frequently used in laboratory evaporation and distillation processes. By creating a vacuum, they lower the boiling point of liquids, allowing for gentler and more controlled evaporation. This is particularly useful for heat-sensitive substances or when precise control over the evaporation process is required. 2. Filtration: Vacuum filtration is a common technique in laboratories for separating solids from liquids or gases. Vacuum pumps create suction, which helps draw the liquid or gas through the filter, leaving the solid particles behind. This method is widely used in processes such as sample preparation, microbiology, and analytical chemistry. 3. Freeze Drying: Vacuum pumps play a crucial role in freeze drying or lyophilization processes. Freeze drying involves removing moisture from a substance while it is in a frozen state, preserving its structure and properties. Vacuum pumps facilitate the sublimation of frozen water directly into vapor, resulting in the removal of moisture under low-pressure conditions. 4. Vacuum Ovens and Chambers: Vacuum pumps are used in conjunction with vacuum ovens and chambers to create controlled low-pressure environments for various applications. Vacuum ovens are used for drying heat-sensitive materials, removing solvents, or conducting reactions under reduced pressure. Vacuum chambers are utilized for testing components under simulated space or high-altitude conditions, degassing materials, or studying vacuum-related phenomena. 5. Analytical Instruments: Many laboratory analytical instruments rely on vacuum pumps to function properly. For example, mass spectrometers, electron microscopes, surface analysis equipment, and other analytical instruments often require vacuum conditions to maintain sample integrity and achieve accurate results. 6. Chemistry and Material Science: Vacuum pumps are employed in numerous chemical and material science experiments. They are used for degassing samples, creating controlled atmospheres, conducting reactions under reduced pressure, or studying gas-phase reactions. Vacuum pumps are also used in thin film deposition techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD). 7. Vacuum Systems for Experiments: In scientific research, vacuum systems are often designed and constructed for specific experiments or applications. These systems can include multiple vacuum pumps, valves, and chambers to create specialized vacuum environments tailored to the requirements of the experiment. Overall, vacuum pumps are versatile tools that find extensive use in laboratories across various scientific disciplines. They enable researchers to control and manipulate vacuum or low-pressure conditions, facilitating a wide range of processes, experiments, and analyses. The choice of vacuum pump depends on factors such as required vacuum level, flow rate, chemical compatibility, and specific application needs.

China wholesaler Stellite Aviation Industry Nickel Alloy Inconel 22 Vacuum Pump Impeller vacuum pump ac systemProduct Description

Q1.Are you trading company or manufacturer? Q4:How to avoid mass order quality problems? /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Disadvantages of using a vacuum pumpA vacuum pump is a device that pulls gas molecules out of a volume and leaves a partial vacuum. Its main function is to create a relative vacuum within a given volume. There are several types of vacuum pumps. Some of them are better suited for specific purposes than others. However, there are some disadvantages to using a vacuum pump. Application of vacuum pumpVacuum pumps are invaluable tools in many industrial and scientific processes. They are often used to move gas and other harmful substances and to clear clogged drains. They are also used to support mechanical equipment. For example, they can be mounted on the engine of a motor vehicle or the power hydraulic component of an aircraft. No matter how they are used, they should fit the application. Their drawbacksVacuum pumps are useful in industrial applications. However, they are not perfect and have some drawbacks. One of them is that their output is limited by the vacuum hose. Vacuum hoses are the bottleneck for vacuum pump performance and evacuation rates. The hose must be kept free of water and organic matter to ensure the highest possible vacuum.

China Best Sales 2be Industrial Water Ring Vacuum Pump CHINAMFG Air Suction Water-Ring Vacuum Pump for Paper Making Factory vacuum pump connectorProduct Description

Product Description 2BE liquid ring vacuum pump is CHINAMFG liquid ring vacuum pump and is used to transport gases and vapors, predominantly for intake pressures below atmospheric pressure. Our 2BE liquid ring vacuum pump is available in 20 models, and is ATEX Certified. It offered It offered Suction capacity from 150 to 38000m³/h. It has reliable operation and economic power consumption. We also have 2BE pump with Partition wall in pump casing special for paper industry. We offer same outline dimensions for bolt-on replacement and equivalent performances with original 2BV liquid ring vacuum pump.

2BE series water ring vacuum pumps and compressors are the products with high efficiency and economical power, which are manufactured by our company integrating with the advanced technology of the imported products from Germany. These series products adopt CHINAMFG and single action structure and have many advantages, such as, compact structure, convenient maintenance, reliable running, high efficiency and economical power. Comparing with the SK, 2SK, SZ series water ring vacuum pumps used widely in our country at present, the 2BE series products are the ideal replacements of them for high vacuum, low power, and running reliability

Product Series Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1